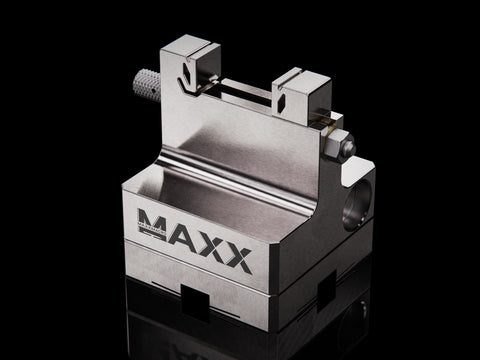

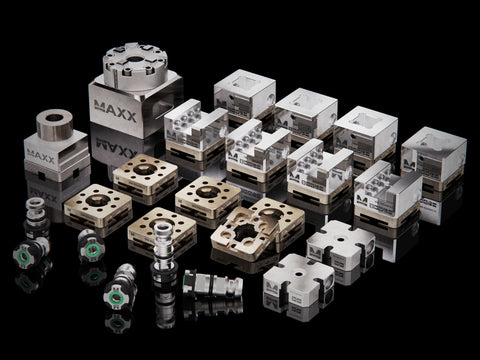

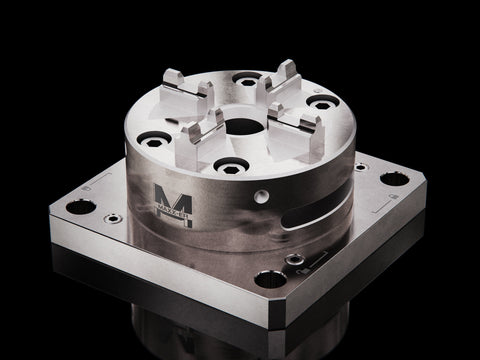

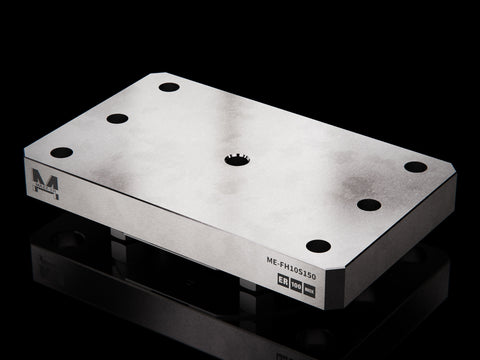

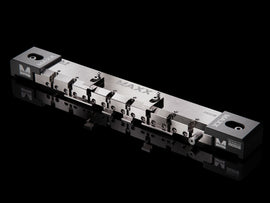

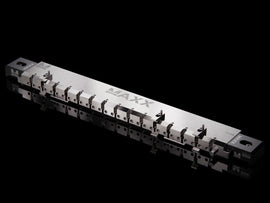

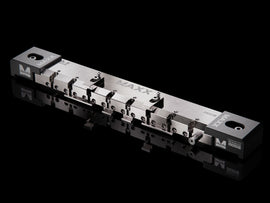

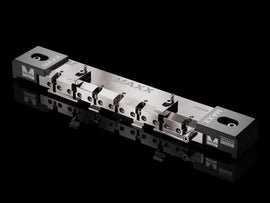

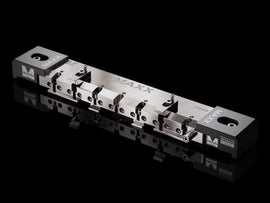

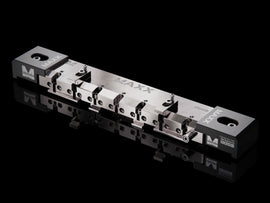

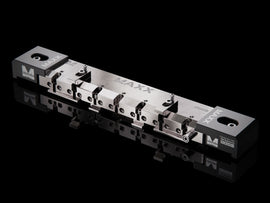

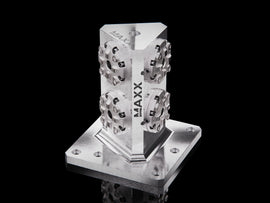

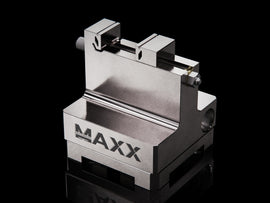

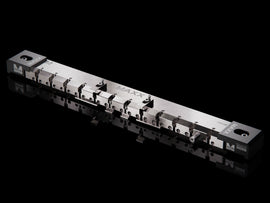

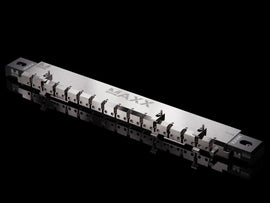

MaxxMacro® Performance WorkHolding

The MaxxMacro® product line from Maxx Tooling offers high-precision chucks, pallets, fixtures and accessories designed for accuracy, durability, and ease of use across various machining applications, including milling, sinker EDM, wire EDM (WEDM), and more. These workholding setups save you valuable time in setup and alignment, while also making it easier to clamp workpieces of different sizes and shapes. Known for their repeatability (0.002mm) and strong clamping force, MaxxMacro® tools ensure stable, damage-free machining. Their robust stainless-steel construction withstands demanding conditions, and quick setup helps boost productivity. Fully cross-compatible with System 3R, MaxxMacro® is a versatile and reliable solution for modern manufacturing environments.